Meat Kingdom

New Distribution

Marketing

- Direct Selling Store

- Location of Stores

- Marketing Schedule

- Marketing Specialties

- Cross Taiwan Strait

- Online Marketing

Innovation

Processed Meat Production

In all of Hsin Tung Yang’s food products, the most famous of all are the dried meat floss and jerky, including pork jerky and beef jerky. Below is the process of making pork jerky, beef jerky and dried meat floss.

Mr. Chiang (photo by: the research team)

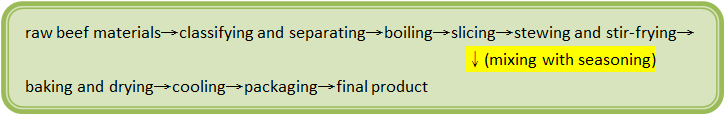

1.Beef Jerky

First, Hsin Tung Yang buys imported fine beef, and they are sent to the factory within thirty minutes after the beef is butchered. Then, the workers classify and separate the beef. Next, they boil the classified and separated beef. After boiling, the beef is cut into a smaller size, and Hsin Tung Yang’s special seasoning is added to the beef at this time, forming different kinds of flavors. Then, it is time for stewing and stir-frying, and this process allows the beef to absorb the flavors of the seasoning. Afterwards, there is a very important step, which is baking and drying. This step allows the beef to become beef jerky, and it seals all the flavors inside. The last step is to cool the beef jerky that is dried and baked. After cooling, the staff then packs up the beef jerky, and it is done!

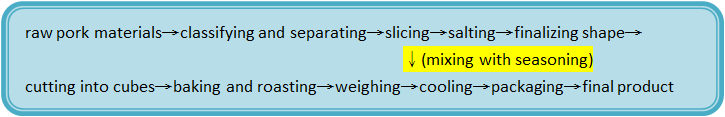

2.Pork Jerky

Hsin Tung Yang selects the pig’s hindquarters as the pork jerky’s material. The first step of making pork jerky is to classify and separate the pork. After classifying and separating, the meat is to be sliced into pieces and mixed with special seasoning. Unlike the beef jerky, the pork jerky is preserved in salt for a while. After salting, the shape is finalized and waits to be cut into cubes. The most important step is to put the pork jerky inside the oven for baking and roasting, which vaporizes the extra water left inside the pork. After baking, the pork jerky is weighed by a special machine to ensure every box of pork jerky weighs the same. After weighing and cooling, the pork jerky is ready to be packaged and it is done!

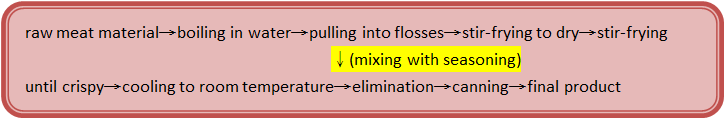

3.Dried pork floss

Within two hours from the time the pig’s hindquarters are butchered, Hsin Tung Yang will cook the meat by boiling to soften the fiber of the meat. Next, the pork is placed into a machine that makes the pork into flosses. Then, special seasonings are mixed with the pork floss and placed into a steam frying pan with some kinako to make the texture fluffy and crispy. Next, the meat floss is moved to the gas revolving boiler to be stir- fried for about 80-100 minutes, and some lard oil is dripped on the meat floss before it is cooked to make it tastier. After cooling, some fiber cubes that were not well-cooked will be removed. A machine then cans, weighs, and packages the dried pork floss on the conveyor belt. When the can is sealed, a jet printer will print on the shelf life. Finally, cans of dried pork floss will be boxed, and it is done!

When making and selling these products, Hsin Tung Yang always emphasizes delicacy and quality. Therefore, from the materials, machines, the production process to packaging, Hsin Tung Yang holds extremely high standards for quality in the hope that they can deliver products at the best quality and everyone can trust in the safety of their food products.

By Stan