| Junyi Cultural and Creative Factory | ||||||

|

Junyi Academy has an annual budget of

30 million of which most are

donations from enterprises and the general public. Non-profit

organizations are very prudent about the use of such

donations.

Children like us are puny in providing financial support which can only

come from our parents. Our plan is to create products that

can be used

to raise fund in the charity sale during school anniversary.

|

||||||

|

||||||

|

|

||||||

|

||||||

|

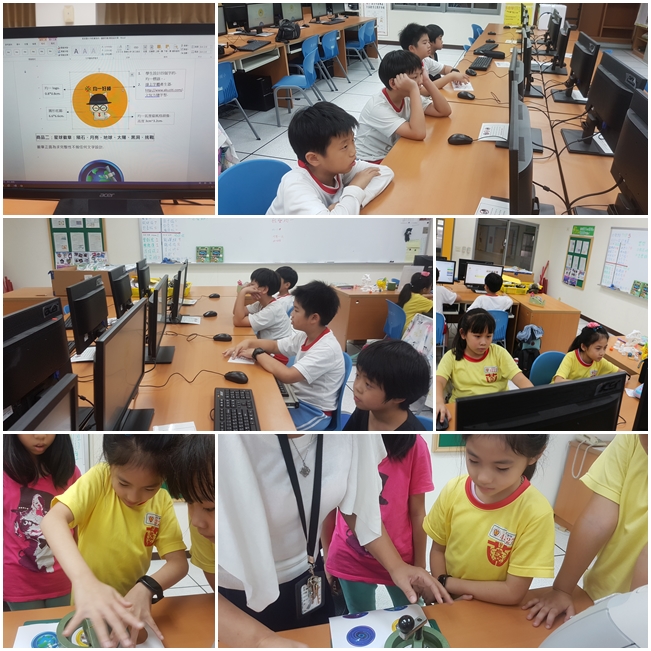

Using computer, we created and printed

out 24 shapes. What comes

next was the production of the medallion whose procedure includes:

i.)Cut the shapes into circles with a radius of 0.3 cm; ii.) Create the body of the medallion by fusing together body material, logo, protective membrane and metal plate; iii.)Packaging the medallion together with a storyline and a thank you note It took a lot of effort and precision to complete a medallion since the procedure is complicated. An imprecision in a step would void the materials. It was a tedious job. Eventually, we segregated the tasks and formed a production-line-like workflow. Looking back on the medallion production, we were very devoted. We were very happy when we saw the final product. We even left other things behind and focused primarily on the production. We were ready before the charity sale. |

||||||

|

||||||

| Filmed by Equally Supreme Team |