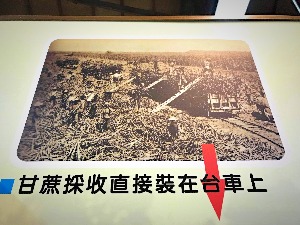

Harvest

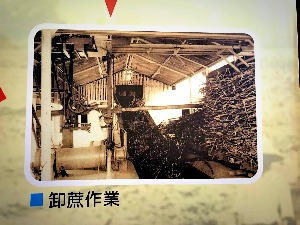

Previous sugarcane harvesting and transport requires a lot of manpower. With the railway raw material , shipping sugar cane to the factory becomes quicker and easier. Because of mechanical harvesters, manpower is needed from 10 people greatly reduced to 2~3 people, not only the manpower was sharply reduced, harvest time is also significantly shortened, and the harvest area is also much greater than it used be.。