Challenges

★Structural Design

Once Jui-Wen Chen had the idea in mind of making the entire road permeable, he then started thinking about the challenges he might face. He asked himself many questions. Can the permeable pavement actually allow water to infiltrate into the soil? Would building a hard roadbed lead to more runoff? If the roadbed were soft, would it cause soil liquefaction when an earthquake hits? Would a soft pavement be able to withstand the weight of the road, or would it break during high traffic volumes? Thus, he wanted to know how he can build a pavement with high permeability and, at the same time, the pavement would be structurally durable enough to withstand the weight of the load.

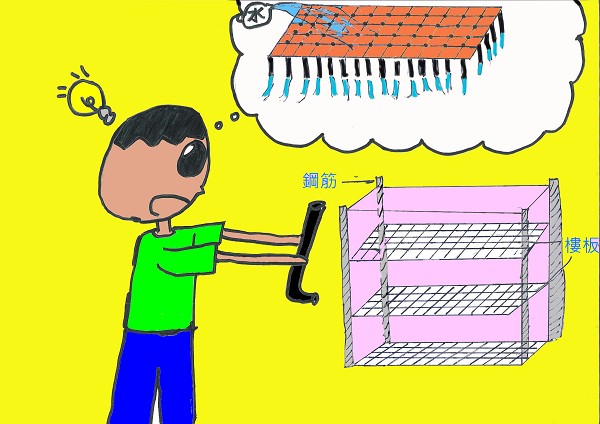

After putting a lot of thought into answering his own questions, Jui-Wen Chen relied on his experience and expertise on building construction to solve the challenges he faced. From his experience, using reinforced concrete with steel bars embedded inside the cement structure would be the most structurally stable and ideal of all building materials. He believed that the reinforced concrete would offer higher durability compared with regular asphalt pavement. Not only that, instead of having to compact the roadbed for the softer asphalt pavement, the reinforced concrete structure only requires a layer of leveled gravel for support.

What about the permeability feature of the pavement? To make pavement with high permeability, he came up with the idea of changing the steel bears in the reinforced concrete into steel pipes, so that, whenever it rains, the water could drain into the pipes and infiltrate through the loose gravel into the soil. Therefore, the concept of an air-circulating Aqueduct Assembly was formed. But then, a new challenge soon emerged – how can it be ensured that the steel pipes would not become blocked or filled with cement during the construction of the frame, especially while the cement is being poured into the frame itself? To solve this problem, Jui-Wen Chen designed a “cap cover” to protect the pipes during the pouring of cement. Once the cement dries, the cap cover could simply be removed with no risks of blocking the pipes.

By Kevin Chang