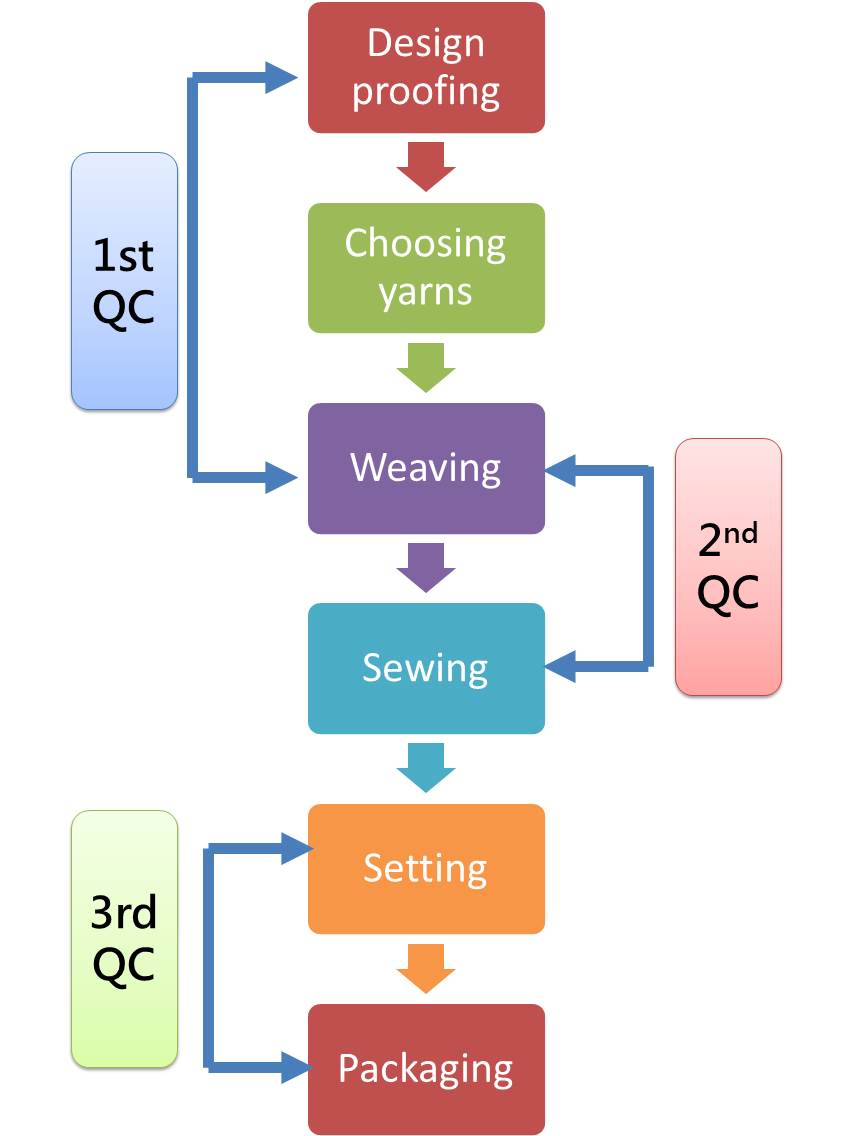

Socks Making Process

| The completion of a pair of socks is complicated with careful procedures. Although there are different opinions on the procedures, most of them are shown as follows. OH9, in these six steps, also carries out strict quality control and stops the increase of defective products, which is commendable. |

|

| <Image Source:Designed by the team> |

| Steps | Phtoto | Step Description |

Design proofing |

|

If a pair of socks can attract consumers, the important factors are the style and pattern on the socks. Therefore, “design” is the most important making step. At present, most of them are designed with computer graphics software. The materialization of artwork is called “proofing”, and the finished product is called “sample”. Then, according to the color matching, the style is modified, and finally, the real product is made. |

Choosing yarns |

|

If a pair of socks can attract consumers, the important factors are the style and pattern on the socks. Therefore, “design” is the most important making step. At present, most of them are designed with computer graphics software. The materialization of artwork is called “proofing”, and the finished product is called “sample”. Then, according to the color matching, the style is modified, and finally, the real product is made. |

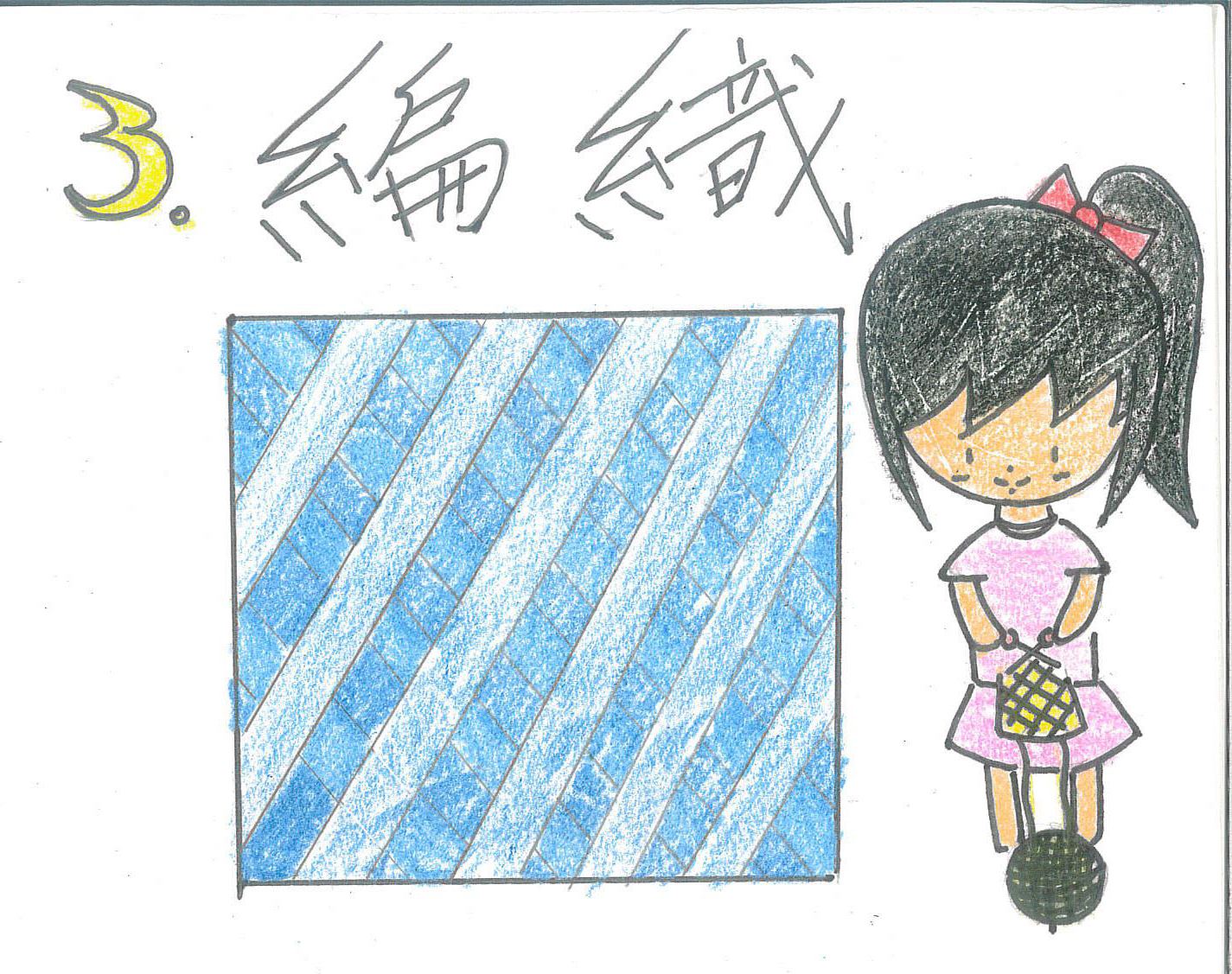

Weaving |

|

After selecting the appropriate yarn type, the size and finished product specifications are set through the computer machine, and then the yarn is placed on the machine in sequence. The computer equipment will automatically produce a variety of socks according to the programming. But here, the sock produced in the labor process has an opening (tube-like socks) at the front toe end of the sock so it can only be regarded as a semi-finished product, also known as “embryo sock”. |

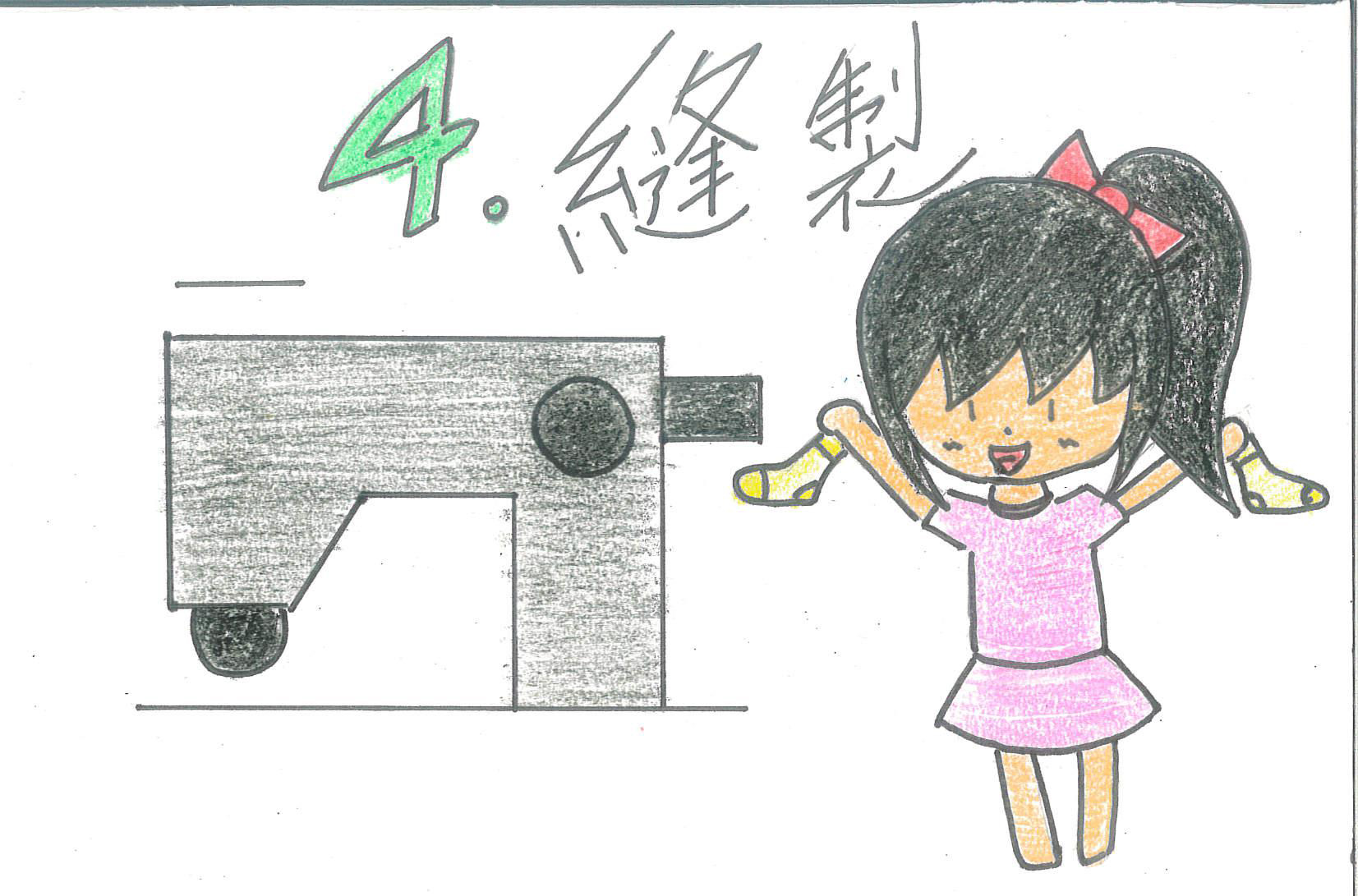

Sewing |

|

After the weaving is completed, the part of the toe is required to be machined and sewn. The sewn socks are also called “Luntou (Taiwanese dialect)”, and the head of the sock is called “seam”. It is important to mention that before sewing, another process called “flip-flops” was done. The simple utensils can be used to turn the socks to the other side. After sewing, turn back to the front. If there is LOGO or embroidery, the procedures of dyeing, bleaching, fixing, dehydrating and drying are needed to be done. |

Setting |

|

The woven and sewed socks must be set, manually shackled in the special iron template to fix the shape and size, and then baked in the oven at high temperature. The high temperature heating of the steam is used to shape socks. After shaping the socks, remove the socks from the template to make a pair of beautiful socks. |

Packaging |

|

After the quality is checked, the socks are manually matched into pairs (also called Double Match). Later, after the socks are fixed with sockets, attached with tags, marked with the size label and worn with the hooks, the socks can be packaged. Each pair is packaged into a plastic bag, or 12 pairs are loaded into a carton. After the packaging is completed, the socks can be shipped. |

| Reference Website Taiwan OH9 Global War Business Weekly |

| <The table and the photos were disigned by the team> |

| <TOP> |